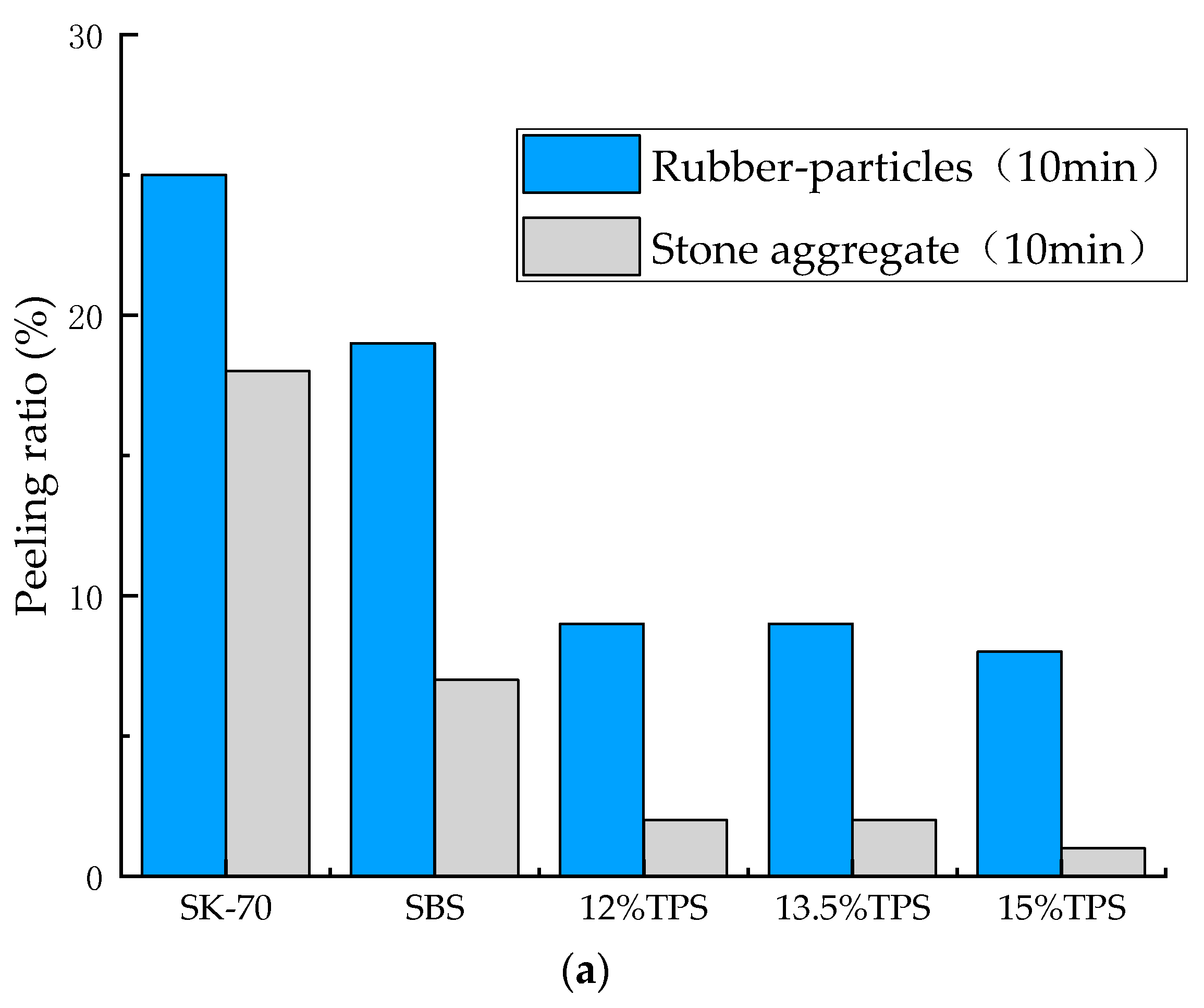

Rubber Adhesion Peel Test

Application spotlight peel adhesion test equipment for adhesives tapes and labels.

Rubber adhesion peel test. The rubber proofed fabric was subjected to ozone irradiation at different doses 250 500 and 1000 ppb. Astm d429 test standard determines the adhesion of rubber to rigid metal substrates. Tack is defined as the force required to separate two sheet materials which are compressed together for a specified. There are many conditions that can affect the adhesion of rubber to various substrates such as metal and fabrics.

It is applicable to either woven or parallel cord textile structures from both natural and manmade fibers and to parallel steel cord structures. The value of interest is the adhesion strength defined as the maximum force divided by the. Common application examples that use tests in astm d429 are vehicle engine mounts vehicle suspension bushings rubber coated metal parts and rubber lined tanks and containers. It is related to the bonding strength of an adhesive to a mating substrate.

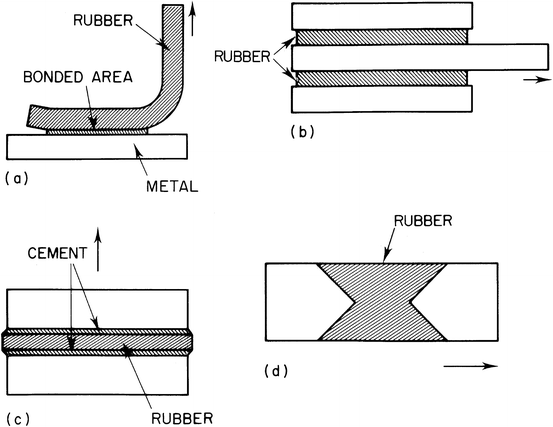

The last comes first. This test standard is divided into methods a through h. Ardl offers a variety of tests to evaluate the adhesion properties of materials and components. Method a describes a tension test used to determine the bond of a rubber part assembled between two parallel metal plates.

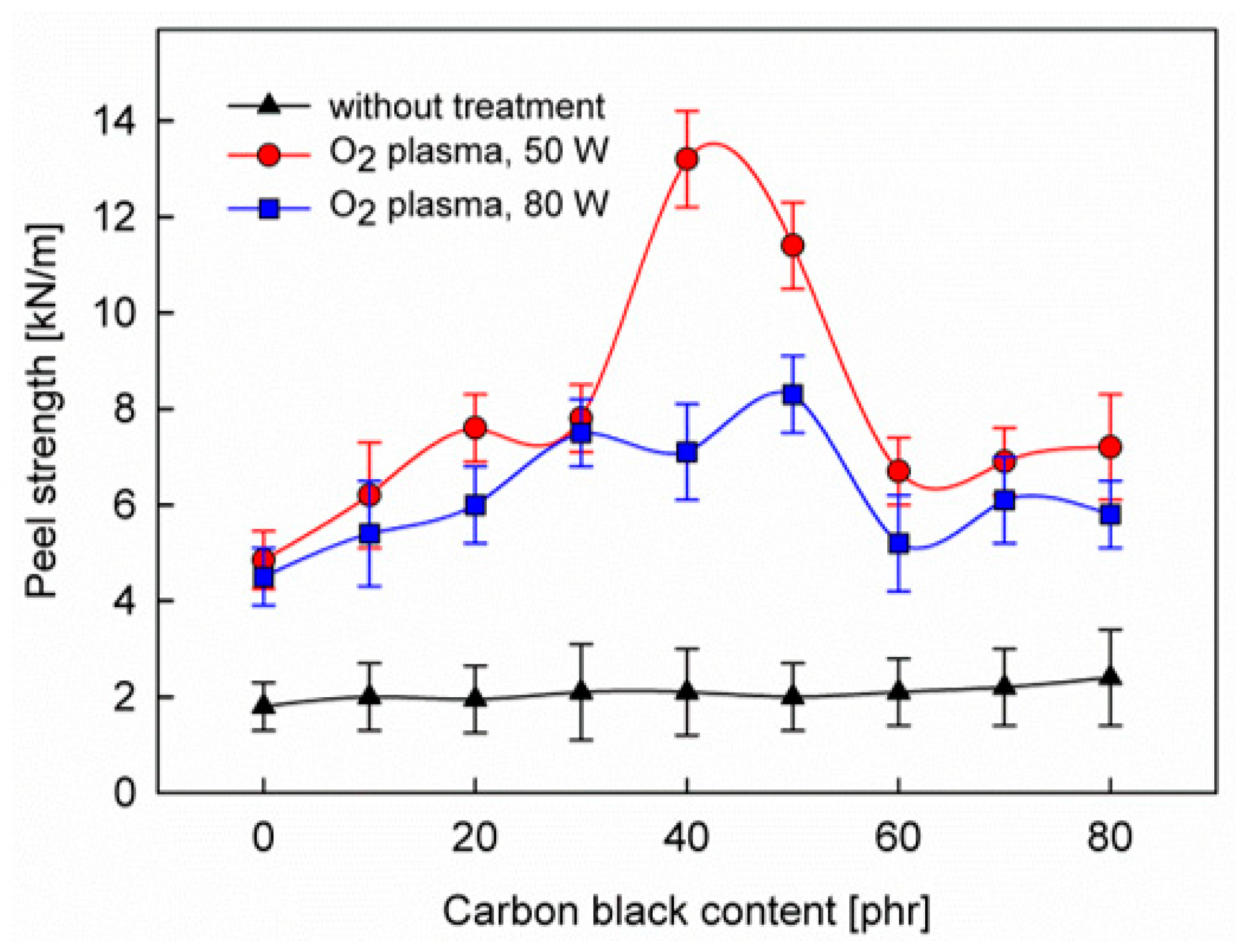

From peel or stripping strength to measurements at temperature ardl can provide the. Some of the very first applications for pressure sensitive adhesives such as bandages labels and masking tapes for painting were evaluated on performance based on how easy or how difficult it was to remove them from the applied surfaces. Picma tack tester the picma tack tester measures the adhesion or tack of rubber materials adhesive tapes sealants and other materials. The peel strength was used to measure the adhesion strength between the fabric and the rubber.

Adhesion testing for rubber adhesion to flexible and rigid substrates as well as the adhesive bonding of parts are an important properties for designers to understand when evaluating materials. Method b describes a peel procedure to determine the adhesive strength between rubber materials to a metal plate or substrate. New peel testing capabilities include 180â peel and t peel measurements.