Rubberized Asphalt Disadvantages

790 11 hot rubberized asphalt is best for two specific applications.

Rubberized asphalt disadvantages. Another waterproofing material is rubberized asphalt. Chemical approaches for the preparation of rubberized asphalt utilize chemical methods and chemical characterization to mitigate the disadvantages associated with rubberized asphalt. Resurface with rubberized asphalt concrete cold mill 1 inch add 2 1 2 inch rac. This material works great for keeping your home protected from the elements.

Early projects the ar that phoenix used consisted of crumb rubber or ground up used tires mixed with liquid asphalt binder. However this can be improved by the incorporation of desulfurized rubber powder. Adding 4 inches to the existing roadway elevation may not be practical. These 60 mil thick membranes are composed of rubberized asphalt laminated to a waterproof polyethylene film.

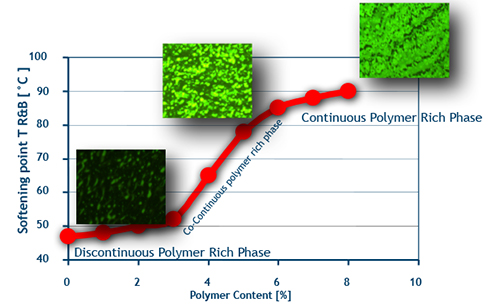

The disadvantage of rubber modified asphalt is associated with the preparation process during heated storage. Asphalt rubber binder typically exhibits disadvantages like segregation and high viscosity. This rubber comes from grinding up recycled tires otherwise headed for the landfill. A higher in place cost is one of the main disadvantages of sheets.

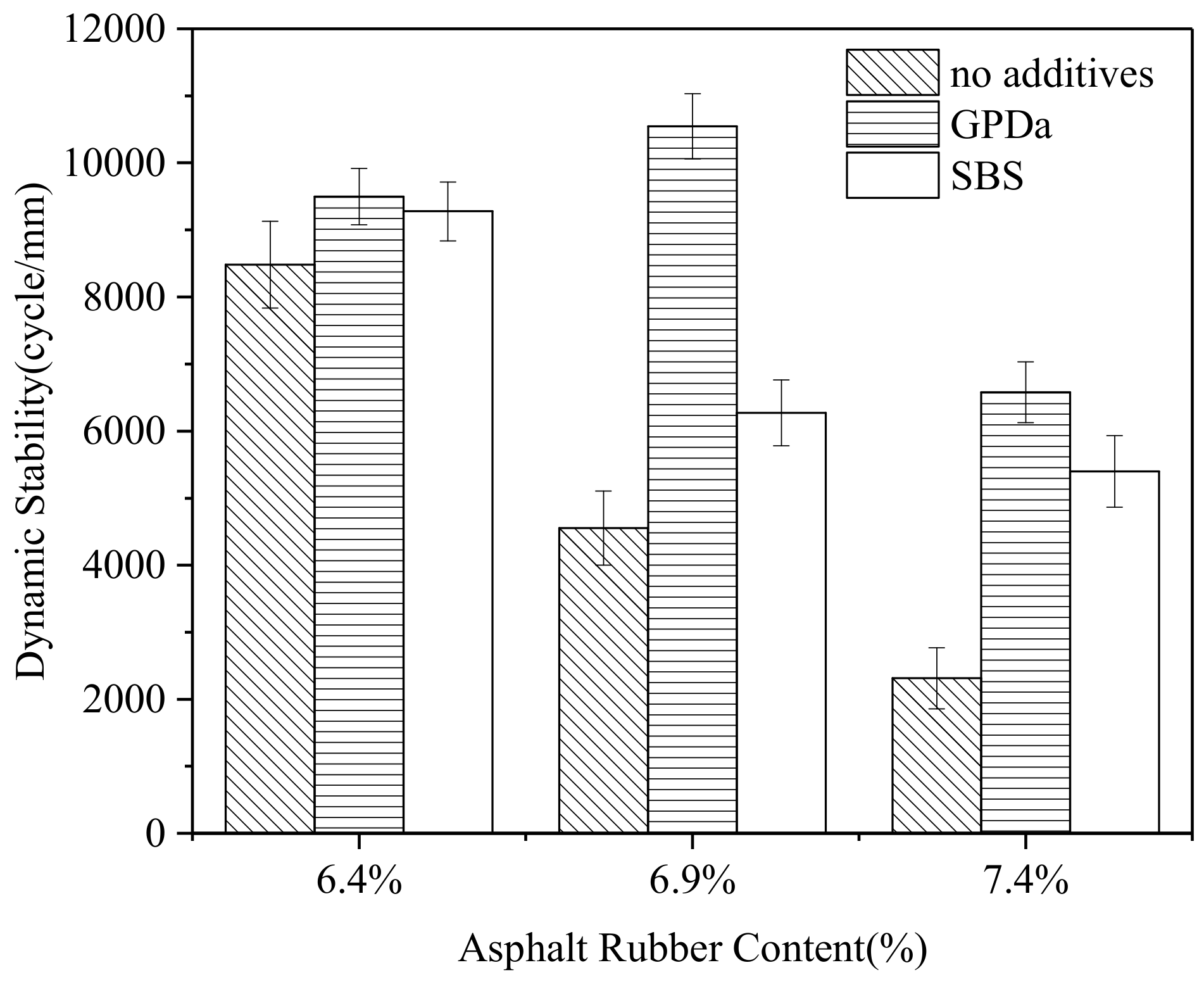

The most commonly specified sheet materials are self adhering rubberized asphalt membranes. Similar in concept to glasphalt it uses a proportion of crumb rubber to replace part of the aggregate. Crumb rubber also referred as ground rubber is one of several available asphalt binder modifiers. This study examined the swelling principle of desulfurized rubber asphalt dra.

It is now enjoying high popularity. In addition it evaluated the performance of dra fabricated with various rubber powder. The improvements using rubber modified asphalt include decreased thermal cracking potholing deformation reflective cracking and ice formation and have extended road life up to three times longer than normal asphalt. In the last decade a number of states and federal agencies have run tests on its durability.

Being the largest market for ground rubber rubberized asphalt consumes an estimated 220 000 000 pounds or around 12 million tires annually. However it is primarily found on roofs for commercial businesses. Rubber from scrap tires or other sources is grinded and blended with asphalt cement to beneficially modify the properties of asphalt forming rubber modified asphalt binder asphalt rubber binder or used as a aggregate substitute in an asphalt concrete paving mixture. Characterization techniques include infrared spectroscopy ir 17 26 27 thermogravimetric analysis tga 28 29 30 and gel permeation.

Ge 2 1 2 x 1 9 x 2 18 8 1 4 26 9.